Welded to Length LENOX CONTESTOR XL Blade Material

LENOX CONTESTOR XL Bandsaw Blades Welded to Length

LENOX CONTESTOR XL Bandsaw Blades Welded to Length

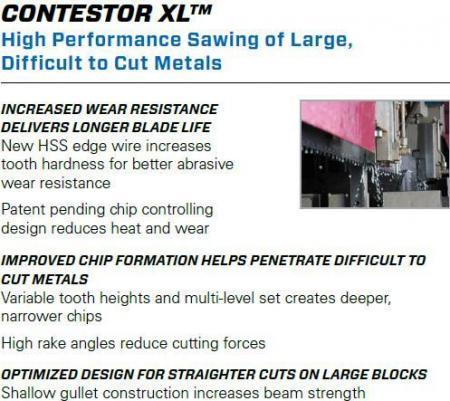

New HSS edge wire increases tooth hardness for better abrasive wear resistance Patent pending chip controlling design reduces heat and wear

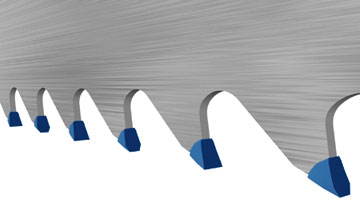

IMPROVED CHIP FORMATION HELPS PENETRATE DIFFICULT TO CUT MATERIALS

Variable tooth heights and multi-level set creates deeper, narrower chips High Rake angles reduce cutting forces

OPTIMIZED DESIGN FOR STRAIGHTER CUTS ON LARGE BLOCKS

Shallow gullet construction increases beam strength

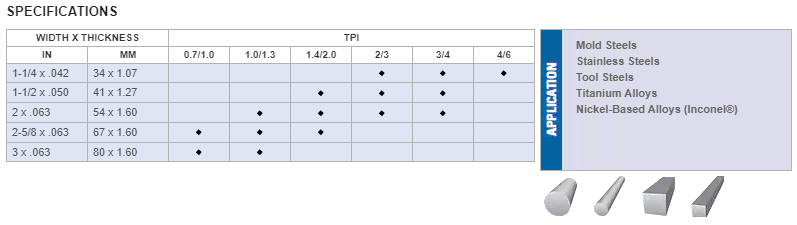

APPLICATION:

Mold Steels, Stainless Steels, Tool Steels, Titanium Alloys, Nickel-Bassed Alloys (Inconel)

Tooth Shape and Set

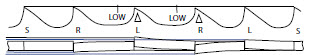

V - Vari-Tooth

Bi-Metal Speed Selection Chart

Bi-Metal Tooth Selection Chart

Purchase

| 30 | -20.00% | $65.47 |

| 20 | -15.00% | $69.56 |

| 10 | -10.00% | $73.66 |

| 5 | -5.00% | $77.75 |

Description

What are the three main types of bandsaw blades?

There are three main types of bandsaw blades: Bi-metal, Carbon Steel, and Carbide Tipped blades. All three have their own characteristics, benefits, and disadvantages when applied to different applications.

How do I choose a bandsaw blade?

In general, for wood cutting, it is recommended to use the widest blade your saw will allow and for radius cuts you will want a narrower width, depending on the radius you want to achieve. Wood Cutting – We offer several styles of wood cutting bandsaw blades for band speeds targeting 3,000 band feet per minute. Flex Back, Neo-Type, Diemaster2, Classic and Tri-Master.

Metal cutting operations require a much slower blade speed (75 to 300 band feet per minute) with the use of general purpose bi-metal blades to specialty blades, designed for very hard material and high production rates.

What is the most useful wood cutting bandsaw blade size?

If any blade could be considered all-purpose, a 3⁄8-in., 6-tpi, carbon-steel blade would be it. This blade has enough width to handle most rip cuts in material up to 2 in. thick without deflecting but is narrow enough to cut mild curves. It's also good for quick crosscuts.

How do I choose a TPI for my bandsaw blade?

The general rule of thumb is:

For wood and soft materials aim for 3 – 12 teeth in the work piece.

When cutting metal is best to refer to a tooth selection chart to help you get best blade performance when cutting.

If you have questions selecting the proper blade, give us a call 1-888-778-9663 x-1

Blade Construction

Blades can be made from one piece of steel, or built up of two pieces, depending on the performance and life expectancy required.Carbon Blades

Hard Back type:

A one-piece blade made of carbon steel with a hardened back and tooth edge.

Flex Back type:

A one-piece blade made of carbon steel with a hardened tooth edge and soft back.

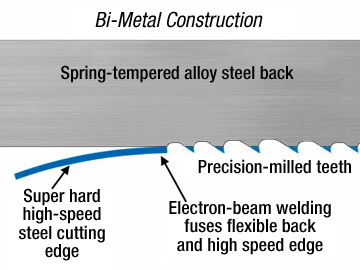

Bi-metal Blades

A high speed steel edge material is electron beam welded to fatigue resistant spring steel backing. Such a construction provides the best combination of cutting performance and fatigue life.

Carbide Ground Tooth Blades

Teeth are formed in a high strength spring steel alloy backing material.

Carbide is bonded to the tooth using a proprietary welding operation. Tips are then side, face and top ground to form the shape of the tooth.

Set Style Carbide Tooth

Teeth are placed in a high strength spring alloy backing material. Carbide is bonded to the tooth and ground to form the shape of the tooth. The teeth are then set, providing for side clearance.

BANDSAW BLADE MATERIAL TYPES

Cutting Wood using a Wood Bandsaw:

- Flex-Back -Carbon Steel Blade - General Wood cutting operations

- Neo-Type - Carbon Steel Blade (Hardback) tooth size 8 to 24 tpi for thin wood and plastics (originally for cutting metal but at 75 to 300 BFPM)

- #32 Wood -Specialized Woodworking Applications

- Diemaster 2 - Bi-Metal blade, provides 6x the life of Carbon Steel blade stock

- Classic - Bi-Metal blade, provides 6x the life of Carbon Steel blade stock

- Woodmaster B - Bi-Metal blade specifically for use on Portable Band Mills also Horizontal and Vertical Re-Saws

- Woodmaster CT - Carbide Tipped for use on Portable Band Mills also Horizontal and Vertical Re-Saws

- Tri-Master - Carbide Tipped Precision triple chip grind results in smooth cuts and excellent finish.

Cutting Metal on a Wood Bandsaw:

- Diemaster 2 - Bi-Metal blade, provides 6x the life of Carbon Steel blade stock

- Matrix - Bi-Metal blade, .020 thick, provides 6x the life of Carbon Steel blade stock

- Classic - Bi-Metal blade, provides 6x the life of Carbon Steel blade stock

- Classic Pro - Bi-Metal blade, provides 6x the life of Carbon Steel blade stock

NOTE:

When using a WOOD Cutting band saw for cutting metal (saw running about 3000 BFPM) hardened metal will not be able to be cut. Bandsaw blade speeds between 75 and 300 BFPM are required to cut hardened materials and receive favorable blade life. If your wood saw has two speeds, use the slow speed for cutting soft metal.

When cutting wood, the Rule of Thumb is 3 to 12 teeth in the work, with the most general purpose count being 6 TPI. The fewer teeth per inch provide a faster, but rougher cut; and more teeth per inch provide a smoother, but slower cut. When resawing use the widest blade suitable for your saw with the fewest number of teeth per inch. Make sure that you select a blade of proper thickness. The continual flexing of the blade causes metal fatigue and failure of the blade. Fatigue is the tendency of a metal to break under continued flexing. The thickness of the blade required depends upon the diameter of the wheels and the work to be done. Thick blades will withstand more strain from cutting than thin blades, but will break more easily from the bending action, especially when run on small wheels. Each revolution flexes the blade to near the elastic limit of the steel, which causes the metal to fatigue and break quickly. Thinner blades are recommended when the work is light.

*Bandsaw Blade Speed BFPM is Band Feet Per Minute

The types of Lenox Band Saw Blade stock listed below

are for general metal cutting to high performance metal cutting operations

Bi-Metal Blade Product Selection Chart

Bi-Metal Speed Selection Chart

Bi-Metal Tooth Selection Chart

LENOX Bi-Metal Band Saw Blades

High speed steel tooth tips combined with flexible alloy steel backing material results in band saw blades that are the most cost effective choice for most metal sawing applications. A wide variety of products are available to ensure optimal blade performance in your application.- Diemaster 2 - Bi-Metal blade, provides 6x the life of Carbon Steel blade stock

- Matrix - Bi-Metal blade, .020 thick, provides 6x the life of Carbon Steel blade stock

- Classic - The Ultimate Multi-Purpose

- Classic Pro -The Ultimate Multi-Purpose Blade for Production Cutting

- QXP - Long Blade Life at High Cutting Rates

- RX+ - Engineered to Cut Structurals, Tubing and Bundles

- Armor RX+ - Engineered for Long Life

- Contestor GT - High Performance Sawing

Carbide Speed Selection Chart

Carbide Tooth Selection Chart

LENOX Carbide Band Saw Blades

High performance backing steel and optimized carbide grades give premium band sawing performance. These band saws will cut faster and last longer than any other band saw blade in a wide variety of sawing applications.

- ARMOR CT BLACK -For Extreme Cutting Rates

- TNT GT - Extreme Performance on Super Alloys

- CAST MASTER -Superior Performance When Sawing Castings

- TRI-TECH CT -Set Style Carbide Blade for Difficult to Cut Metals

- TRI-MASTER -Versatile Carbide Tipped Blade

- ALUMINUM MASTER CT -Triple Chip Tooth Design

- HRc -Carbide Tipped Blade for Case and Through-Hardened Materials

- MASTER GRIT -Carbide Grit Edge Blade for Cutting Abrasive and Hardened Materials

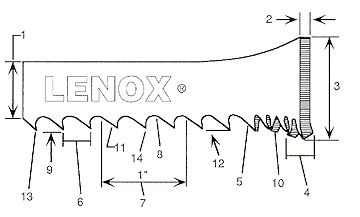

Bandsaw Blade Terms

A clear understanding of blade terminology can help avoid confusion when discussing cutting problems.

- - The body of the blade not including tooth portion.

2. Gauge

- - The thickness of the blade.

3. Width

- - The nominal dimension of a saw blade as measured from the tip of the tooth to the back of the band.

4. Set

- - The bending of teeth to right or left to allow clearance of the back of the blade through the cut.

5. Tooth

- - The cutting portion of a saw blade.

6. Tooth Pitch

- - The distance from the tip of one tooth to the tip of the next tooth.

7. TPI

- - The number of teeth per inch as measured from gullet to gullet.

8. Gullet

- - The curved area at the base of the tooth. The tooth tip to the bottom of the gullet is the gullet depth.

9. Gullet Depth -

- The distance from the tooth tip to the bottom of the gullet.

10. Tooth Face

- - The surface of the tooth on which the chip is formed.

11. Tooth Back

- - The surface of the tooth opposite the tooth face.

12. Tooth Back Clearance Angle

- - The angle of the tooth back measured in relation to the cutting direction of the saw.

13. Tooth Rake Angle

- - The angle of the tooth face measured with respect to a line perpendicular to the cutting direction of the saw.

14. Tooth Tip -

- The cutting edge of the saw tooth.

15. Kerf

- - Amount of material removed by the cut of the blade.

BAND SPEED

The rate at which the band saw blade moves across the work to be cut. The rate is usually measured in feet per minute (fpm) or meters per minute (mpm).

BASE BAND SPEED

List of recommended speeds for cutting various metals, based on a 4" wide piece of that stock.

BI-METAL

A high speed steel edge material electron beam welded to a spring steel back. Such a construction provides the best combination of cutting performance and fatigue life.

BLADE WIDTH

The dimension of the band saw blade from tooth tip to blade back.

CARBIDE TIPPED BLADE

Carbide tips welded to a high-strength alloy back, resulting in a longer lasting, smoother cutting blade.

CARBON FLEX BACK

A solid one-piece blade of carbon steel with a soft back and a hardened tooth, providing longer blade life and generally lower cost per cut.

CARBON HARD BACK

A one-piece blade of carbon steel with a hardened back and tooth edge that can take heavier feed pressures, resulting in faster cutting rates and longer life.

CUTTING RATE

The amount of material being removed over a period of time. Measured in square inches per minute.

DEPTH OF PENETRATION

The distance into the material the tooth tip penetrates for each cut.

Tooth Form and Construction

As with a bi-metal blade design, there are advantages to differing tooth constructions. The carbide tipped tooth has carbide tips welded to a high strength alloy back. This results in a longer lasting, smoother cutting blade.

Tooth Form

The shape of the tooth’s cutting edge affects how efficiently the blade can cut through a piece of material while considering such factors as blade life, noise level, smoothness of cut and chip carrying capacity.

Variable Positive - Variable tooth spacing and gullet capacity of this design reduces noise and vibration, while allowing faster cutting rates, long blade life and smooth cuts.

Variable - A design with benefits similar to the variable positive form for use at slower cutting rates.

Standard - A good general purpose blade design for a wide range of applications.

Skip - The wide gullet design makes this blade suited for non-metallic applications such as wood, cork, plastics and composition materials.

Hook - Similar in design to the Skip form, this high raker blade can be used for materials which produce a discontinuous chip (such as cast iron), as well as for non-metallic materials.

Tooth Set

The number of teeth and the angle at which they are offset is referred to as "tooth set." Tooth set affects cutting efficiency and chip carrying ability.

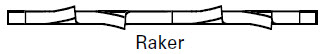

Raker:

3 tooth sequence with a uniform set angle (Left, Right, Straight).

Modified Raker:

5 or 7 tooth sequence with a uniform set angle for greater cutting efficiency and smoother surface finish (Left, Right, Left, Right, Straight). The order of set teeth can vary by product.

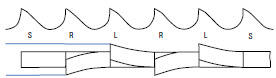

Vari-Raker:

The tooth sequence is dependent on the tooth pitch and product family. Typically Vari-Raker set provides quiet, efficient cutting and a smooth finish with less burr.

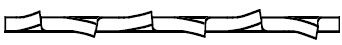

Alternate:

Every tooth is set in an alternating sequence. Used for quick removal of material when finish is not critical.

Wavy:

Groups of teeth set to each side within the overall set pattern. The teeth have varying amounts of set in a controlled pattern. Wavy set is typically used with fine pitch products to reduce noise, vibration and burr when cutting thin, interrupted applications.

Vari-Set:

The tooth height / set pattern varies with product family and pitch. The teeth have varying set magnitudes and set angles, providing for quieter operation with reduced vibration. Vari-Set is efficient for difficult-tocut materials and larger cross sections.

Single Level Set:

The blade geometry has a single tooth height dimension. Setting this geometry requires bending each tooth at the same position with the same amount of bend on each tooth.

Dual Level Set:

This blade geometry has variable tooth height dimensions. Setting this product requires bending each tooth to variable heights and set magnitudes in order to achieve multiple cutting planes.

Selecting Bandsaw Blade Width, Thickness and TPI

If you have a two wheel bandsaw and do not know the length of the blade,

this

will help you find the length.

GO HERE

Choosing the Correct Bandsaw Blade Width

Blade width is measured from the tips to the teeth to the back edge of the blade body.

The instructions for the particular bandsaw being used should be followed when selecting blade width.

If no such instructions exist, the blade width should be determined with the following guidelines:

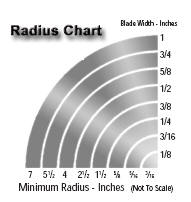

Cut-Off Sawing (Re-sawing)

The blade selected should be as wide as the machine will allow, keeping in mind the blade thickness and wheel diameter.

The wider the bandsaw blade is, the straighter the cut will be.

The bandsaw blade should be as wide as the machine allows,

but still narrow enough so that it can cut the desired shape (radius).

Minimum dimensions for different cutting radii are shown in the radius chart

How to Choose the Correct Number of Teeth Per Inch (TPI)

The number of teeth per inch (TPI) is important in obtaining the finish desired and the proper feed rate. A coarse tooth blade (2, 3 TPI) should be used for re-sawing wood and cutting thicker stock up to 8" thick. A fine toothed blade (18 to 32 TPI) should be used for thinner metals and plastics under 1/4". For general cutting of 3/4" plywood 6 TPI will provide a fast cut and 14 TPI will cut much slower but leave a smooth finish on the cut.

When Selecting TPI Remember:

- More TPI gives a smoother but slower cut.

- Fewer TPI allows for a faster cut with a slightly rougher cut surface.

- Should have at least 3 teeth and less than 12 teeth in the work piece.

Band Saw Blade Thickness

The thickness of a bandsaw blade is determined by the thickness of the blade body. Bandsaw blades vary in thickness .014", .018", .020", .022", .025", .032", .035", .042", .050", .063".

Make sure that you select a blade of proper thickness. The continual flexing of the blade causes metal fatigue and failure of the blade. Fatigue is the tendency of a metal to break under continued flexing.

The thickness of the blade required depends upon the diameter of the wheels and the work to be done. Thick blades will withstand more strain from cutting than thin blades, but will brake more easily from the bending action, especially when run on small wheels. Each revolution flexes the blade to near the elastic limit of the steel, which causes the metal to fatigue and brake quickly. Thinner blades are recommended when the work is light.

This chart offers Guidelines for selecting Blade Thickness for wheel diameters.

WHEEL DIAMETER RECOMMENDED

BLADE THICKNESS4-6 inches

6-8 inches

8-11 inches

11-18 inches

18-24 inches

24-30 inches

30 inches

and over.014"

.018"

.020"

.025"

.032"

.035"

.042", .050", .063".014", .018" .020" thicknesses are no longer available in Lenox brand

It is not always possible to adhere to the above recommendations due to the cutting operation you intend to perform and the particular band saw you are using. To maintain extended fatigue life of the blade, select the thinnest blade possible that will offer you the appropriate number to TPI to perform you cutting operation.

- Fewer TPI allows for a faster cut with a slightly rougher cut surface.

Have a question?

Have a question?